Prototype mold is a process that is used to create a small number of parts for testing purposes. It is ideal for creating a small batch of parts or prototypes, as it allows for rapid iteration and design changes.

Developing a new trolly involves a process that requires taking an idea from conception to a tangible and functional prototype. The journey from concept to mold to prototype is a critical step in the development of all MediFocus trolley.

The first step is to get the requirements from customer about the trolly appearance and function. This process can begin from many sources. These sources include customer feedback, extensive market research, and the implementation of new technologies. Once this has been established, the next steps can be taken to bring the concept to trolley product.

After the initial idea is established, it is time to put the concept into a practical design. This design must reflect the necessary specifications and measurements of the trolley. During this part of the process, drawings and 3D models are created. All factors must be taken into account, such as materials, function, cost, and aesthetics.

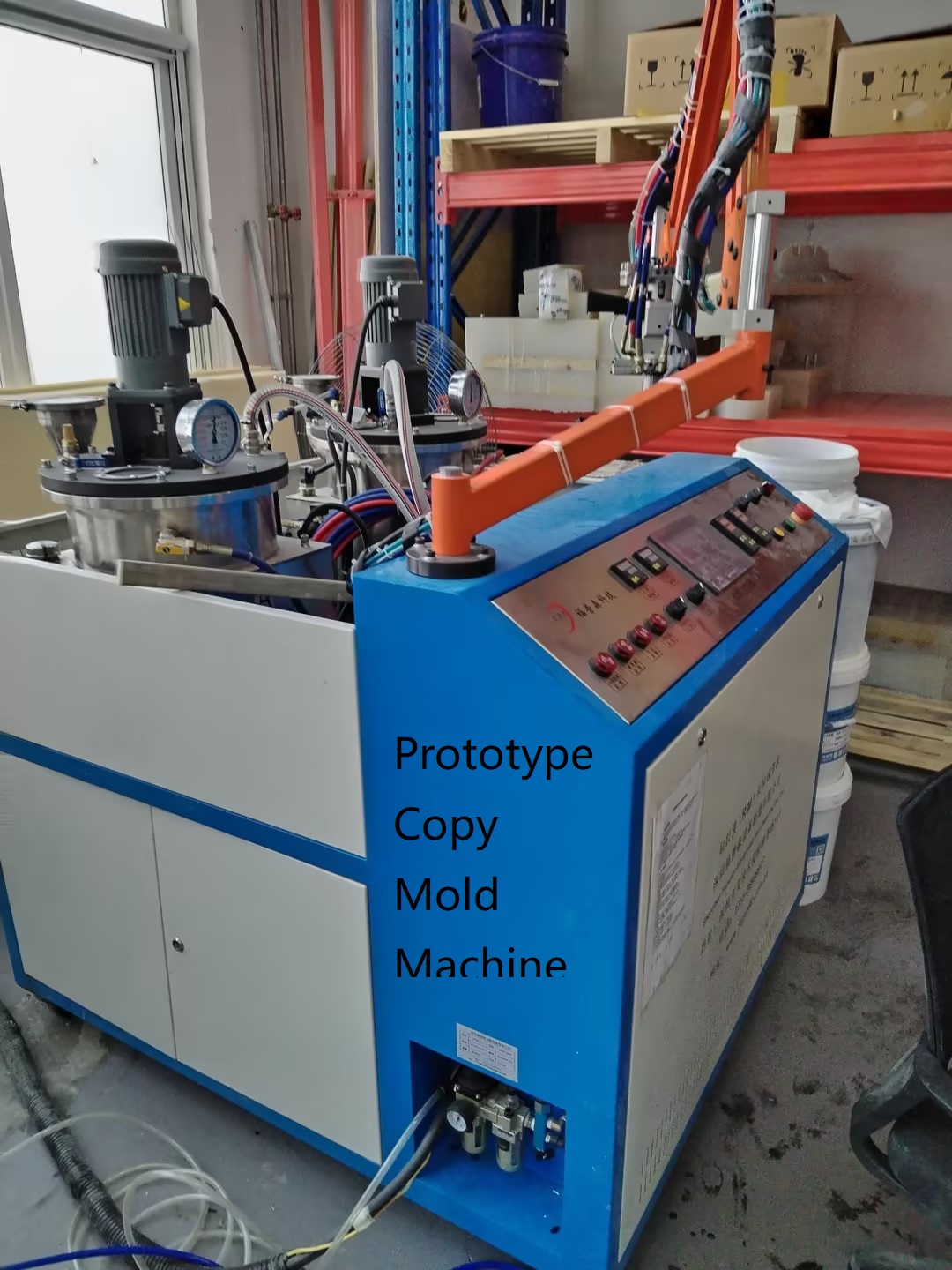

Designers consider prototyping to be a very important step after the design process. It enables them to inspect and confirm their design and its components prior to manufacturing. The techniques of prototyping may range from 3D printing, CNC machining, or manual creation, depending on how intricate the design is.

Post time: May-13-2024